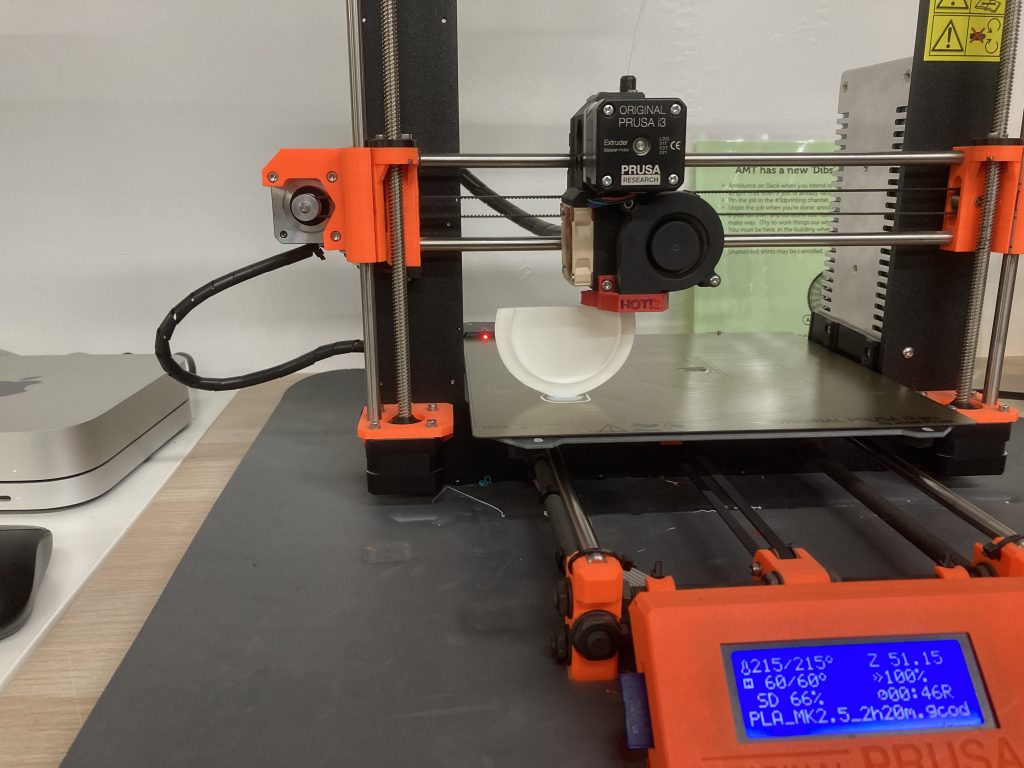

My original reason for learning about 3D printing was so that I could make indoor golf discs. The first 3D printer I used was at Ace Makerspace in Oakland, CA.

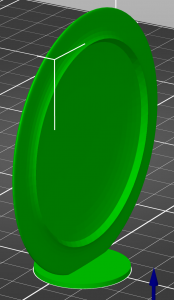

I watched Lars Christensen’s Fusion 360 videos on YouTube until I could draw golf discs. Then I struggled to print them until I finally tried to print them on their edges and then it worked.

I originally envisioned some kind of handheld launcher. I actually designed one and printed it, but it turned out to be easier to just throw the discs, thankfully.

The discs behave like regular-sized golf discs. All the same kinds of throws possible with a regular golf disc are available with a smaller version, but the throwing techniques are different.

You can explore smalldiscgolf.org for details about how to 3D print golf discs and tips for indoor and outdoor play. It is all free and open source. Discs cost about a quarter in filament to print (0.25 US Dollars). The site has eight unique disc design you can print. They all behave differently so you can shape your shots.

One great thing about these small discs is it doesn’t take a lot of strength to throw them. Indoors you probably could never need more than a quick toss. Being able to impart spin is the most important skill because then the discs fly the way you would expect them to fly. Without enough spin all discs are badly understable. smalldiscgolf.org also contains links to videos showing several different techniques for throwing.